SAV(SAV Spann-Automations-Normteiletechnik GmbH)

German SAV is producer and supplier of clamping, automation and load lifting systems. High quality, precision and cost-efficiency .

Contacts

Brand Overview

Thinkfon Industry has reached a strategic cooperation agreement with SAV to become its designated agent in East and Southeast Asia

SAV has over 180 employees and sales exceeding 30 million euros. Almost half of them were generated in the fields of magnetic clamping technology and fixed clamping technology. Almost every task is a special solution. Only well-trained experts can work and receive training in SAV.

SAV's customers include the automotive, mechanical engineering, medical technology, aerospace, steel structure, and tool and mold manufacturing industries. But distributors and industrial end users from various fields have also found competent partners here. Because our customers benefit from the following advantages: reduced complexity, higher efficiency, reduced costs, and higher security.

Thinkfon Industry is the designated agent for SAV in East and Southeast Asia

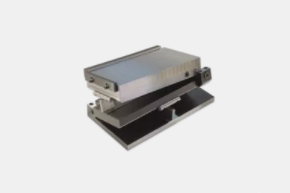

SAV Main Products

|  |  |  |

| Surface grinding | milling | turn | drilling bit |

|  |  |  |

| Clamping magnetic strip | WEDM | Vertical and horizontal axis rotation | automation |

SAV application field

Workpieces are the focus of customers in the SAV automotive industry. Therefore, the task in charge is to customize the workpiece processing according to the customer's requirements, until small details are achieved. This requires in-depth process knowledge and extensive professional knowledge in mechanical engineering. Ensure stable quality and compliance with all safety standards, even in mass production. The equipment of SAV can withstand all possible loads and has a long service life. Collaborate with customers to develop innovations that have been successfully established in the automotive market.

Provide appropriate clamping techniques. Especially in this field, SAV sees itself as the fundamental connection between the workpiece and the machine. Due to SAV considering itself as a machine manufacturer, it is possible to fully understand customer needs and conduct in-depth research. This not only promotes cooperation, but also convinces customers of the importance of understanding their respective goals to them.

In the aerospace industry, the innovation capabilities of SAVs are in demand in various aspects. Many new developments require adaptation of production technology. Meeting these challenges is not a problem for us experts.

Whether it's steel processing or heavy steel beam assembly: With SAV, customers can find suitable contacts and solution seekers around them to complete this demanding task. In production, milling magnets and magnetic welding auxiliary equipment used for heavy-duty machining make the processing of this large material easier. In the field of assembly, the ability to perform magnetic loads and heavy-duty structures is certainly particularly popular. The lifting system is safe and reliable, and importantly, it can be customized according to various customer requirements.

Tool and mold manufacturers are important interfaces between product concepts and the final results of the product development process. Efficiency, economy, and high quality are always at the forefront. A natural requirement for SAV products. Therefore, the device is the correct choice. Because they are very precise, they can ensure large repeatability accuracy. Whether it is a special solution or a standard solution.

Products

producet testType:0022200 producet testType:0022200 |